- europages

- >

- Lame circolari

- >

- CAS TECH

- >

- prodotti

CAS TECH

Italia

Fabbricante/ Produttore

CAS TECH

Italia

For cutting of sections and the tubular thickness from 2 to 5 millimeters of aluminum, PVC and non-ferrous metals . They use it on miter saws and table saws . No-noise sawblades with a special sound absorbing resin inside the silent slots.

Chieda un preventivo

CAS TECH

Italia

One way miter cutting (from 0 degree to 60 degrees). Cast-iron sawframe on twin tapered bearings and ring nut to provide greater stability.Precision blade-guide with bearings and anti-corrosion treatement.Machine bed in thick metal works exclusively made by domestic workshops.High level machining and finishing of the parts. Vice and sawframe in cast-iron providing high stability and vibration free cutting. Mechanical blade tension with handwheel.Precision blade-guide with roller bearings. Anti-corrosion treatment with electrolytic nickel-plating and galvanization zinc plating ensure long lasting cutting precision. Electric motor and reduction unit from domestic ISO certificated manufacturers. Electric installation according CEE regulations. Set of fuses against current overload. Motor protected thermal feeler. Safety microswitch on the blade protection. Coolant liquid with electropump and crucible.

Chieda un preventivo

CAS TECH

Italia

Motor power HP (KW) 5,5 (4) Cast iron fly wheels Ø mm 800 Width – fly wheel mm 40 Cutting width mm 785 Max cutting height mm 500 Width of the belt mm 10 ÷ 45 Speed’s belt m/sec 25 Dimensions of the working table mm 1130 X 800 Net weight kg 620 Electric system according to norms Self-braking motor Tilting cast iron table 0° ÷ 20° Safety protections according to norms 3-phase motor HP 7,5 3-phase motor HP 10 Saw blade Adjustable bottom saw blade guide Mitre quadrant Compass Curve catch Squaring fence (fixed on two bars for all its length)

Chieda un preventivo

CAS TECH

Italia

N° 3 motors Kw (Hp) 5 (6,6) 3-knives shaft Ø mm 72 Rotation’s speed of the planer shaft r.p.m. 5100 Ø suction hoods mm 120 Overall dimensions of the surfacing tables mm 1800X410 Overall dimensions of the thickness table mm 410×605 Working height min / max mm 3/230 In-feeding speed m/1’ 7 Overall dimensions of the sliding table mm 240×2250 Capacity of cutting between saw blade and fence mm 820 Length of cut mm 2310 Ø saw blade mm 315 Ø scorer blade mm 80 Height of cut with blade at 90° mm 100 Rotation’s speed of the saw blade shaft r.p.m. 4000 Rotation’s speed of the scorer shaft r.p.m. 7600 Ø max tool mm 210 Spindle working length mm 125 4-speeds of the spindle shaft r.p.m. 1400 / 3500 / 6000 / 8000 Overall dimensions of the mortising unit’s table mm 430X220 Mortising unit’s longitudinal/transversal/vertical stroke mm 155x115x100 Wescott chuck of the mortising unit mm 16 Net weight kg 560 Overall dimensions with packing mm 2400x1300x1300

Chieda un preventivo

CAS TECH

Italia

Main motor (saw blade) Kw (Hp) 4 (5,5) Scorer motor Kw (Hp) 0,55 (0,75) Overall dimensions of the carriage mm 3200×340 (420 optional) Length of cut from the scorer’s blade mm 3200 Capacity of cutting saw blade/fence mm 1250 Overall dimensions of fixed cast iron table mm 840X530 Ø saw blade mm 300 – 350 Ø scorer blade mm 100 Height of cut with Ø 300 (Ø 350) blade at 90° mm 95 (120) Rotation speed of the saw blade shaft g/1’ 4500 Rotation speed of the scorer shaft g/1’ 8700 2 suction hoods for connection to the suction system 60/100 Net weight kg 620 Self-braking motor Low tension electric system Support for the suction tube Saw protection with suction installation (compulsory for CE version with a Ø 350 mm saw blade) Carriage of 3200 x 420 mm sliding with ball-bearings Carriage of 3200 x 420 mm sliding by a rolls’ system on rectified bars Motor HP 7,5 1-phase motors (saw blade HP 3; scorer blade HP 0,75) Widia scoring blade Ø 100 mm

Chieda un preventivo

CAS TECH

Italia

Machines for parquet industry Specially designed for cutting doors, door frames, base boards and skirtings, it is ideal for installers of parquet or such other floor coverings as carpets, ceramic, etc... Equipped with a powerful motor it provides a clean and precise cut easily and quickly. The cutting height and depth are adjustable by means of its milimetric gauges. Its cutting depth allows to cut the doors at once. Includes dust collection nozzle and pipe for connection to an external dust collector. It cuts door frames without to di- sassemble the butt straps, providing a precise and clean cut. Its cutting depth allows it to cut the doors at once without splintering High fiability when cutting base-boards or skirtings. Thanks to the possibility to take away the front part of the head it is possible to arrive to the corner when cutting the skirtings. Cutting a shadow joint.

Chieda un preventivo

CAS TECH

Italia

TECHNICAL DATA: Main motor (saw blade) Kw (Hp) 11 (15) Overall dimensions of the carriage mm 3200×420 Length of cut mm 3200 Length of cut from the scorer’s blade mm 1250 Overall dimensions of fixed cast iron table mm 1180X670 Ø saw blade mm 550 Height of cut with Ø 550 a 90° mm 200 Rotation speed of the saw blade shaft g/1’ 3000 – 4000 – 5000 2 suction hoods for connection to the suction system. mm 100/120 Net weight kg 1100 STANDARD EQUIPMENT: Electric system with overload protection and emergency switch Manual delta/start switch Motorized up/down of the saw blade Anodised alu carriage sliding on steel rails by means of a ball-bearings system Index of the saw blade’s tilting Squaring fence with goniometer for cutting angles Goniometer with fixed positions at 7,5° – 15° – 18° – 22,5° – 30° – 36° – 45° Clamping device Wide out-feeding table extension Extensible roll at table’s extension Mitre fence (1.

Chieda un preventivo

CAS TECH

Italia

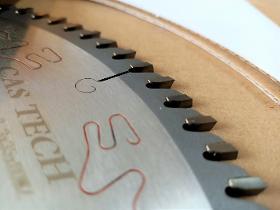

For cutting hardwoods, double sided veneer and laminate board, MDF, hard paper and thermoplastic boards, alucobond. Extra finish and long cutting life. For table saws. with new technology for a more precise cut

Chieda un preventivo

CAS TECH

Italia

Saw blades for cutting across grain of exotic and hardwood, for cutting double-sided veneer boards, single sided laminate boards, MDF and hard boards. Suitable for table saws and panels saws. Suitable for particle board in stack. Benefits: Excellent finish Max rpm: 8000 alternate top bevel teeth.

Chieda un preventivo

CAS TECH

Italia

Applications:All metals in tubing, profiles and small solids (Example: Carbon steel, stainless steel, etc.). Best choice for manual / semi-automatic machines and short blade lengths Benefits:Strong, wear resistant tooth stays sharp longer 2450x27, 2480x27, 2950x27 Vari-tooth: 10/14 - 8/12 - 6/10 - 5/8 - 4/6 - 3/4 - 2/3 - TPI tooth: 14 - 10 - 8 - 6 - 4 - 2

Chieda un preventivoFabbricante/ Produttore

S.S.554 km 4,200

09047 Selargius - Italia

europages ti raccomanda inoltre

Una selezione di aziende vicine all'attività:

Richiesta di preventivi

Crea una richiesta e ottieni più preventivi da fornitori verificati

- Solo fornitori rilevanti

- Rispetto della privacy dei dati

- 100% gratuito