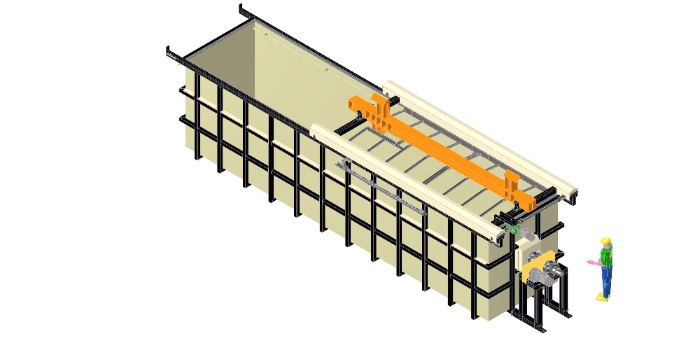

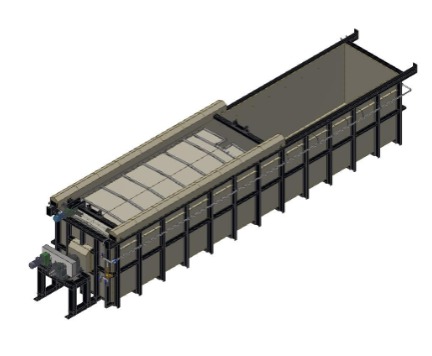

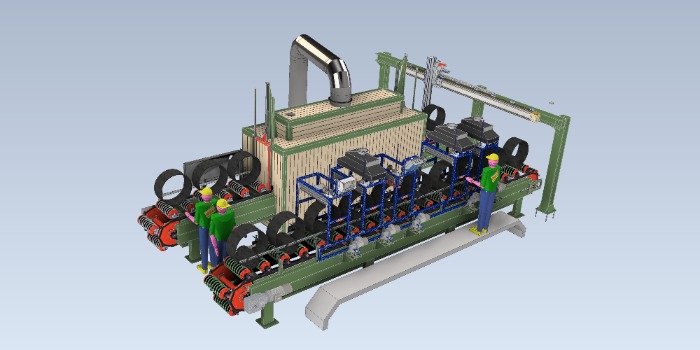

Semi-automatic painting line for OTCG couplings

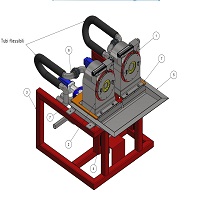

Ultima realizzazione ・ 20 dic 2021 ・ leggi di più...TECNOLOGIE INDUSTRIALI SRL - We are engineered and constructed the semi-automatic painting line for OTCG couplings for this range of coupling from 9 5/8” to 24 1/2". The characteristics of the painting line are: – No.02 Transfer chains: the plant is equipped with a chain for transfer the couplings inside the drying furnace and another one to come back the couplings after the rings marking, stencil and die stamping to the unload position at the side of the load position (the plant is as a “U” shaped line). – No.01 Transfer manipulator: this is an equipment for movement the couplings from the first transfer chains to the second chain. – No.01 Rings painting station: this is a station for painting the identification rings on the couplings surface. – No.01 Stancil marking: this is the station where the plant mark with an alphanumeric and Datamatrix code each coupling. – No.01 Stamp marking: this is the station where the plant punches the alphanumeric